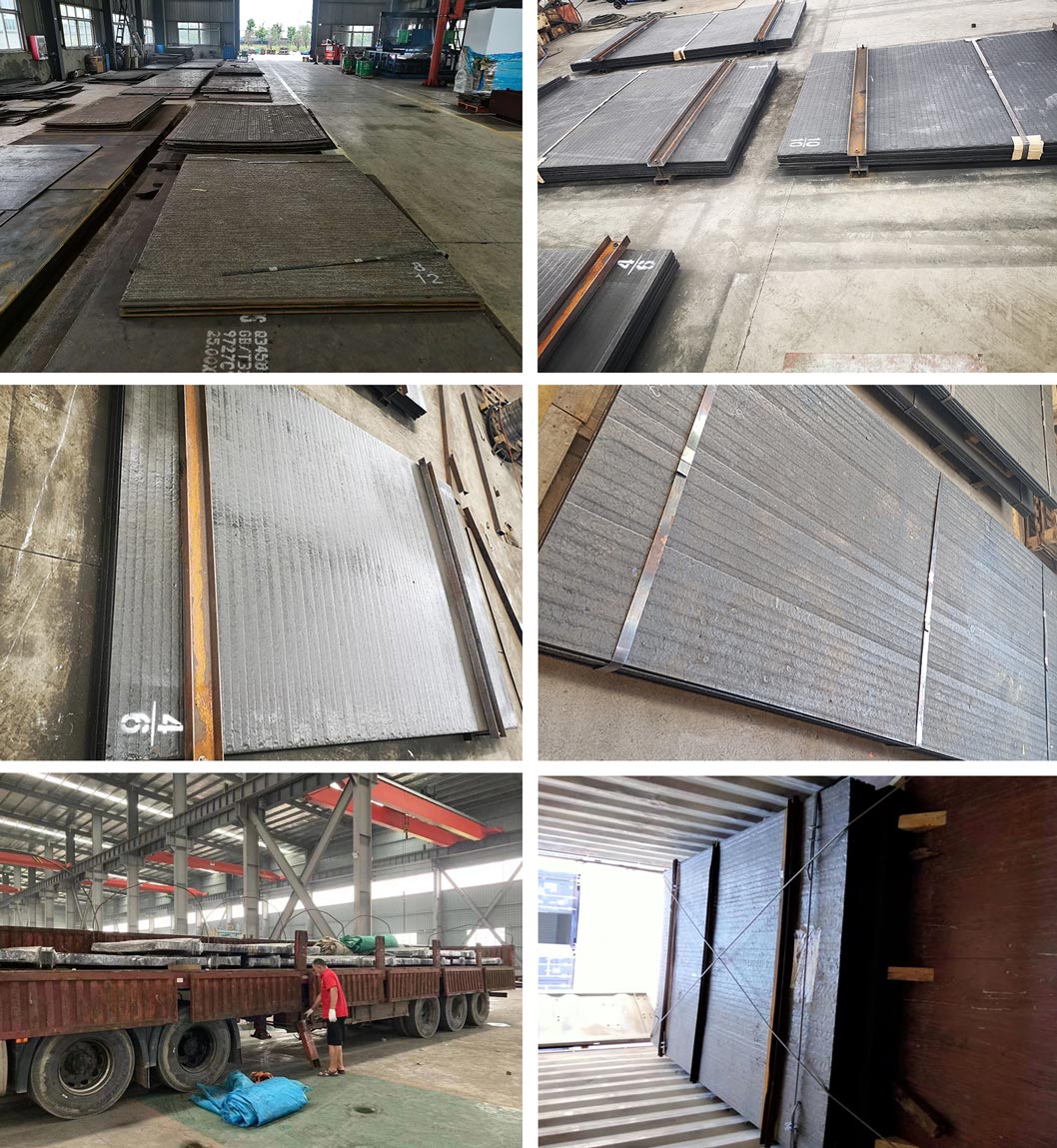

Clad Welding Wear Resistance Plates

If you are looking for a wear plate supplier to supply you with wear plates and wear steel components, then you have come to the right place. In addition to the best solutions and good service, we can also offer competitive prices for wear plates and wear steel parts.

Thickness: 3+3, 4+4, 5+5, 6+6, 8+8, 10+10, 12+12

Size: 1400mm*2000mm, 1500mm*3000mm, 2000mm*3000mm and Customized Size

VIDEO

SPECIFICATION

Get the ultimate protection for your equipment with our clad welding wear resistance plates!

| Chemical Composition of Deposited Metal (Wt%) | ||||||

| Thickness | C | Si | Mn | P | S | Cr |

| 3+3 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-22 |

| 4+4 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-23 |

| 5+5 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 20-23 |

| 6+6 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 24-38 |

| 8+8 | 3.5-4.5 | 0.5-1.2 | 0.5-1.0 | - | - | 27-31 |

Clad welding wear resistance plates are high-performance metal plates designed to withstand extreme wear and tear in industrial and mining applications. These plates are made by welding a layer of wear-resistant material onto a base material, creating a durable and long-lasting product that can withstand harsh operating conditions.

JINHUA tungsten carbide covered wear plate, a unique chromium carbide covered plate, is located on a mild steel base. Its excellent wear resistance and abrasion resistance ensures longer equipment life while reducing maintenance costs.

Produced using a unique and versatile automated batch welding method, tungsten carbide covered wear plates are made from the highest quality raw materials and offer superior wear resistance and high durability compared to mild steel. Our fully automated production methods and quality control procedures ensure that the product has uniform chemical analysis and hardness throughout the composite layer.

The base material used is primarily carbon steel, which allows the final product to be easily welded and formed in complex structures. Other steels can be used as substrates, including stainless steel, AR and other special steels as required by the customer in specific applications.

Plates and fabrications offer excellent wear resistance and can be easily installed on all types of equipment, extending their service life while providing cost-effective protection.JINHUA's design, fabrication and manufacturing expertise ensures an increased return on your wear investment, thus giving you peace of mind.

Wear resistance plates are considered one of the most important things that manufacturing and industrial companies need. If you own one, then you have probably considered using wear plates; but what are they really for?

Many industries need to use wear plates for one or more of the machine parts they own:

Prevent excessive and premature wear

Avoid damage such as scratches, cracks, burrs, etc.

Increase or extend the life expectancy of a part

Chute liners

Bucket liners

Dump truck pallets

Feed plates

Crusher liners

Chute liners

Pipe work

Screen plates

Mobile Equipment

JINHUA can also custom manufacture wear plates to meet your specific requirements. JINHUA will help you select the right and best wear resistant products, using JINHUA developed machine made wear plates and wear resistant steel parts and help you import them from China to your plant.

If you are looking for a wear plate supplier to supply you with wear plates and wear steel components, then you have come to the right place.

Even though wear plates for wear-resistant steel are now very mature, JINHUA can always strive to make wear plates even better.

In addition to the best solutions and good service, we can also offer competitive prices for wear plates and wear steel parts.

1. Plant Introduction

We have equipped with our own developed wear plate hardfacing machine, including single torch, double torch and quadrule torch wear plate hardfacing machine, total 25 uints hardfacing machine.

ADVANTAGE

Superior wear quality (25 times more durable than mild steel, as verified by ASTM G65)

Uniform hardness and chemical composition

Tough austenitic matrix supporting hard carbides

Good heat resistance up to 500°C (932°F) for AB 200 and up to 600°C (1112°F) for AB 400 high temperature

Flat and smooth surface

Good integration with the backing plate, minimal penetration

Mild steel backing plate, easy to weld

Cold forming

Inner roll diameter as small as 250mm

Low dilution of alloy

Multiple sizes and thicknesses

Extremely competitive pricing

TAGS

Copyright © Jinhua (Qingdao) Hardfacing Technology Co., Ltd. All Rights Reserved |

Sitemap

| Technical Support: