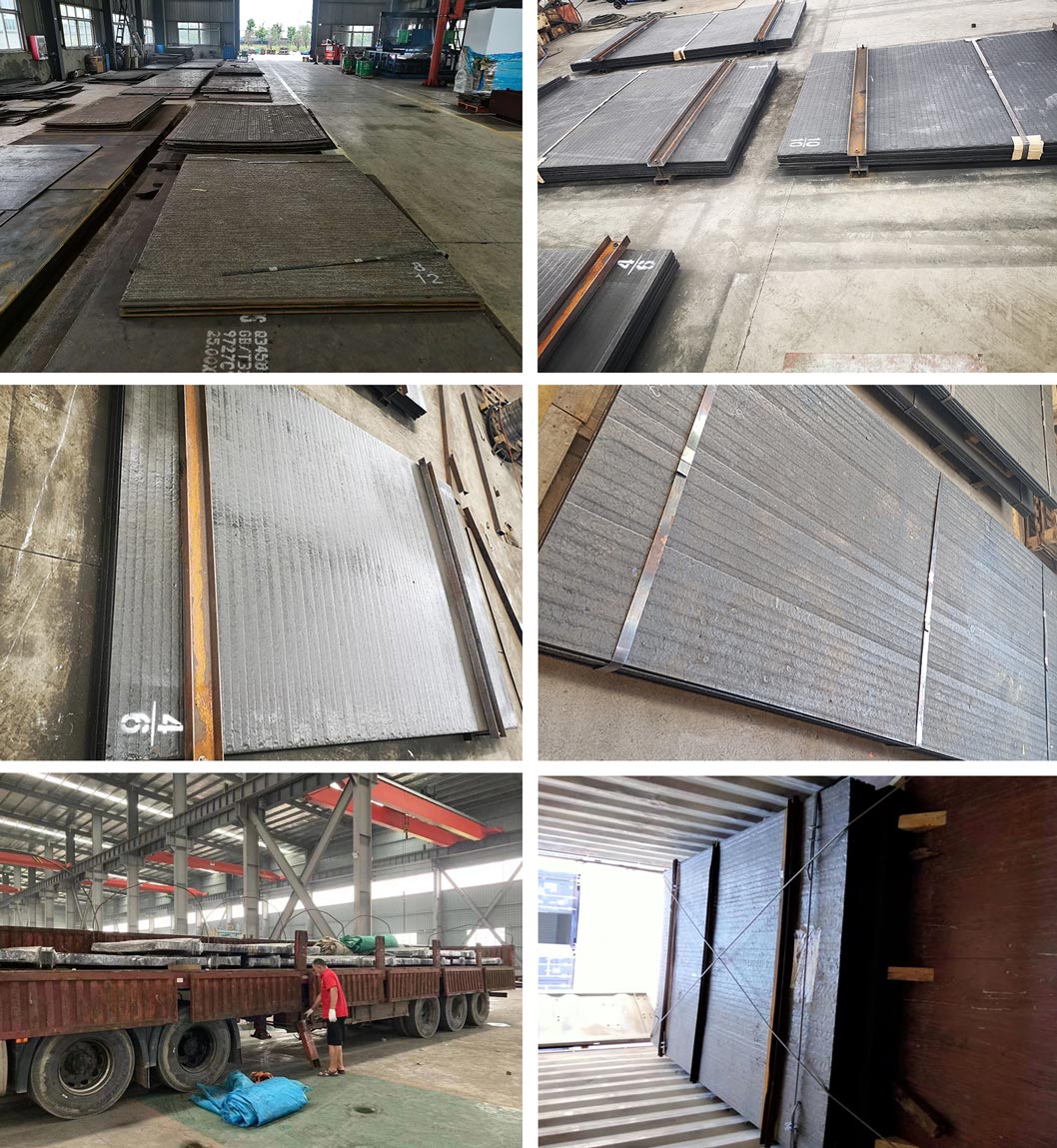

Wear Plate

Thickness: 3+3, 4+4, 5+5, 6+6, 8+8, 10+10, 12+12

Size: 1400mm*2000mm, 1500mm*3000mm, 2000mm*3000mm and Customized Size

VIDEO

SPECIFICATION

Chemical Composition of Deposited Metal (Wt%) | ||||||

| Thickness | C | Si | Mn | P | S | Cr |

| 3+3 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-22 |

| 4+4 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-23 |

| 5+5 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 20-23 |

| 6+6 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 24-38 |

| 8+8 | 3.5-4.5 | 0.5-1.2 | 0.5-1.0 | - | - | 27-31 |

We have equipped with our own developed wear plate hardfacing machine, including single torch, double torch and quadrule torch wear plate hardfacing machine, total 25 uints hardfacing machine.

ADVANTAGE

Abrasion resistant wear plates are high-strength, durable materials designed to withstand severe wear and tear in demanding environments. These plates are commonly used to protect surfaces from abrasion, impact, and erosion, thereby extending the life of equipment and structures.

Extended Equipment Life:Significantly reduces the frequency of part replacements.Decreases maintenance costs and downtime.

Improved Performance:Maintains the efficiency and productivity of equipment by reducing wear-related breakdowns.Enhances the overall reliability of machinery.

Cost-Effective:Though initially more expensive, the long-term savings in maintenance and replacement costs make abrasion resistant wear plates a cost-effective solution.

Versatility:Suitable for a wide range of industries and applications.Can be customized to meet specific needs, ensuring optimal performance.

Mining: In the mining industry, wear plates are used in equipment such as chutes, hoppers, truck beds, and crushers. They protect surfaces from the abrasive nature of minerals and rocks.

Construction: Wear plates are utilized in construction machinery, including excavator buckets, bulldozer blades, and concrete mixers, to protect against wear from earth and construction materials.

Agriculture: In agricultural equipment, such as plows and tillage tools, wear plates help reduce wear caused by soil and debris.

Manufacturing: Wear plates are used in manufacturing processes involving high levels of abrasion, such as in conveyor systems, mixers, and material handling equipment.

TAGS

Copyright © Jinhua (Qingdao) Hardfacing Technology Co., Ltd. All Rights Reserved |

Sitemap

| Technical Support: