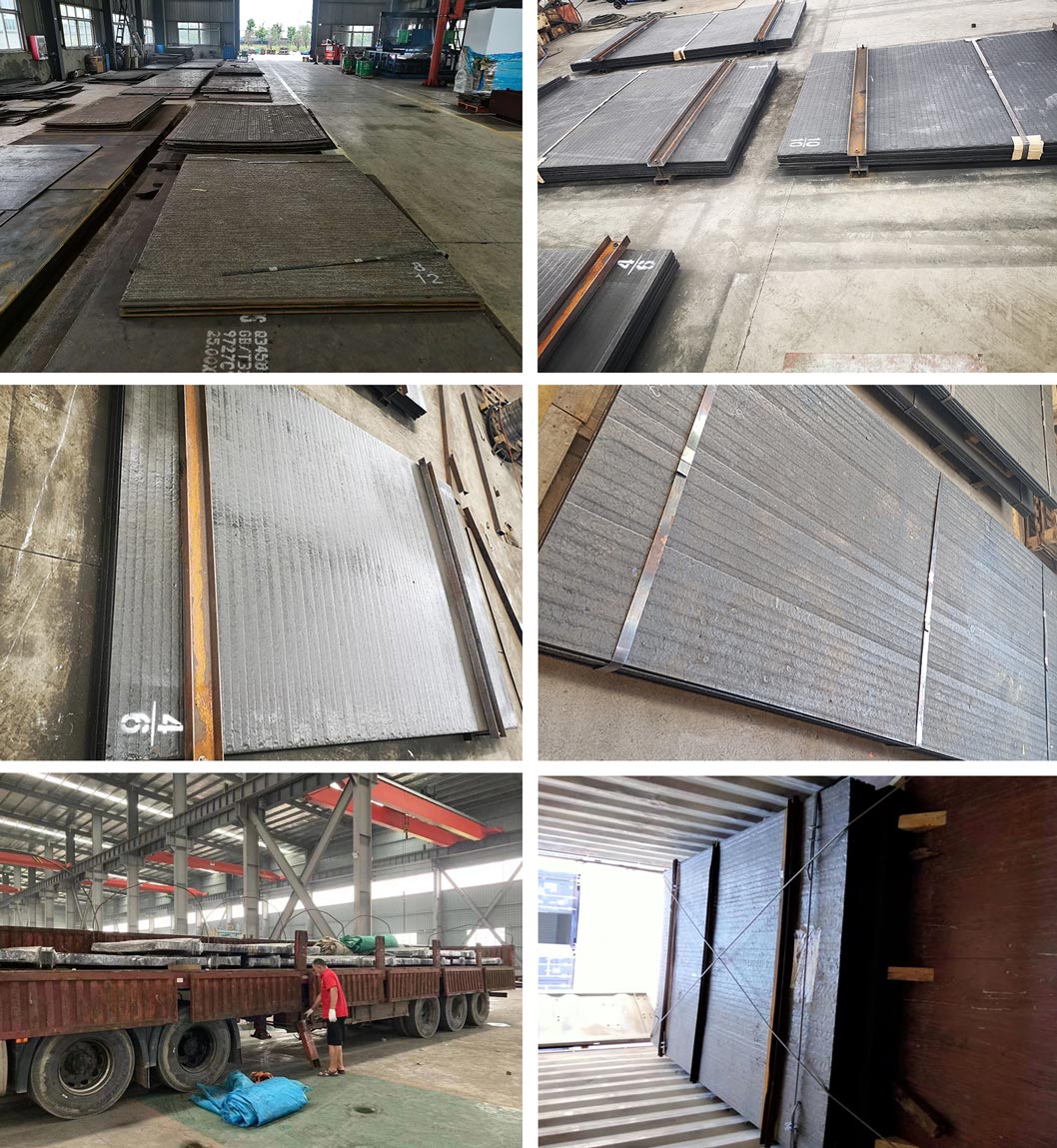

Wear Resistance Plate

Thickness: 3+3, 4+4, 5+5, 6+6, 8+8, 10+10, 12+12

Size: 1400mm*2000mm, 1500mm*3000mm, 2000mm*3000mm and Customized Size

JINHUA, founded in 1996, is a global leader in the innovation and production of hardfacing wire and wear-resistant welding equipment. With over 20 years of experience, JINHUA specializes in providing complete welding automation solutions tailored to various industries, including mining, agriculture, recycling, and construction. Partnering with TELF AG and utilizing top-grade FeCrHC from Kazakhstan, JINHUA delivers superior quality hardfacing consumables. Certified to ISO 9001 standards, JINHUA is committed to offering reliable, high-quality products that exceed industry expectations across sectors such as petroleum, automotive, and aerospace.

VIDEO

SPECIFICATION

| Chemical Composition of Deposited Metal (Wt%) | ||||||

| Thickness | C | Si | Mn | P | S | Cr |

| 3+3 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-22 |

| 4+4 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-23 |

| 5+5 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 20-23 |

| 6+6 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 24-38 |

| 8+8 | 3.5-4.5 | 0.5-1.2 | 0.5-1.0 | - | - | 27-31 |

HARDNESS | HRC 58‐62 | |||||

CHEMICAL COMPOSITION | C | Cr | Mn | Si | Fe | Other |

(wt %) | > 4.5 | > 23.5 | 1.7 | 1.8 | Bal. | ‐ |

STANDARD THICKNESS (mm) | 10 (6+4) | |||||

Customized thickness is available. | ||||||

STANDART SIZE (mm) | 1200 x2900 | |||||

Customized size is available. | ||||||

TOLERANCE | + 1.5mm | |||||

‐0.5 mm | ||||||

OPERATION TEMPERATURE | < 850 oC (> 550 HV) | |||||

ASTM G65 Procedure A | 0.14‐0.19 (Undiluted Deposit) | |||||

MICROSTRUCTURE | Hexagonal carbide imbeds in tough austenitic and martensitic matrix. | |||||

Volume fraction of primary carbides is 30 % | ||||||

MACHINABILITY | Flame cutting, Plasma cutting, Saw cutting, Laser cutting, Water jet | |||||

cutting, EDM, Gouging, Countersink, Stud bolt | ||||||

FORMABILITY APPLICATION | Minimum Radius: 150 mm ( for 6+4, with overlay inward) Suggested: using Cement industry to bend JH‐X750 Ash pipe lines, Elbow, Duct, Bucket, Sinter breaker bar, Drag lines, Conveyor casing, Chute & Hopper liner, Classifier, Ore chute, Fan blade, Cyclone, Discharge funnel, Slag chute, Grizzly bar and so on | |||||

Jinhua specializes in the production of wear resistant steel plates and regularly offers a wide range of grades and thicknesses as well as custom fabrication capabilities.

Wear-resistant steel plates for mining, excavation and heavy machinery manufacturing.

Wear-resistant materials are used in wear applications that require resistance to increased impact and sliding. Wear resistant materials are tested by hardness and wear resistance standards to measure the expected performance and life cycle of the steel plate in wear or abrasion resistant applications.

Because of its versatility and flexibility, you can use it for a wide range of applications. Wear-resistant steel sheets are commonly used in energy, industrial manufacturing, infrastructure and other applications. Other applications include:

Mining

Construction

Material handling

Its most notable features include:

Excellent and extreme hardness

Outstanding service life

No compromise on structural properties

High toughness (resistance to cracking and deformation)

Consistency at high impact and high temperatures

We have equipped with our own developed wear plate hardfacing machine, including single torch, double torch and quadrule torch wear plate hardfacing machine, total 25 uints hardfacing machine.

Copyright © Jinhua (Qingdao) Hardfacing Technology Co., Ltd. All Rights Reserved |

Sitemap

| Technical Support: